Common turbo failure – oil leaks

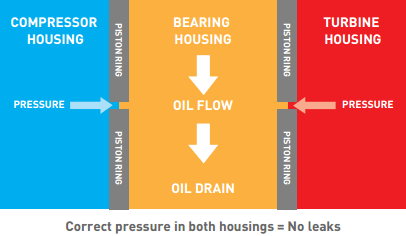

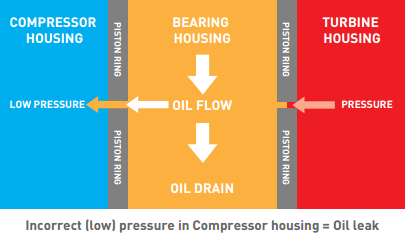

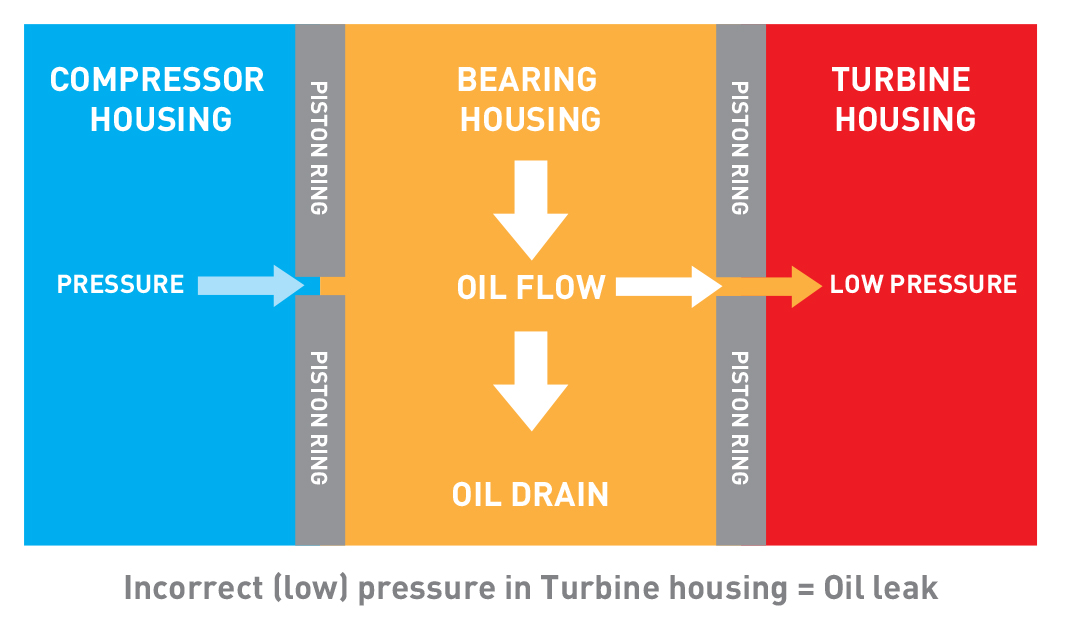

Oil is very often overlooked as a critical component. Oil leaks can be caused by a variety of factors which often originate around the correct pressure within the compressor and turbine housing.

When an oil leak occurs it is important not only to think of the piston ring as the seal, but consider the flinger/ bearing housing bore, piston rings as well as the pressure in the housings as a complete ‘seal assembly’ – these all work together to create a seal.

If any one part of the seal assembly is faulty it can have adverse effects on the other parts in the ‘seal assembly’. For example, a piston ring and flinger bore can be geometrically correct, but oil leaks still occur on the compressor side. This is because the third piece of the puzzle, the pressure, is not correct. If the original cause of failure is not identified it is likely the same type of failure will occur on the remanufactured turbo.

Oil leaks can cause catastrophic damage to the bearing systems and occur within seconds of the turbocharger commencing operation. To help you identify and prevent oil leaks from reoccurring when carrying out a repair, we have highlighted some of the main causes and the signs of oil leaks.

Causes of oil leaks to the compressor outlet:

- Blockages or restrictions to the air intake pipe, hose or filter can create a vacuum, causing oil to leak into the compressor housing;

- Air leaks in the intake hoses or at the intercooler.

Causes of oil leaks to the turbine outlet:

- Leaks within the exhaust system;

- A clogged bearing housing;

- Leaks in the EGR (exhaust gas recirculation) system.

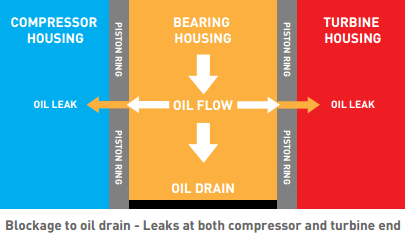

Causes of oil leaks at both the compressor and turbine outlets:

- Restricted or blocked oil drain pipe from the turbocharger to the engine;

- Restriction, or clogging, of the crankcase ventilation system;

- Repeated hot engine shutdowns leading to carbon deposits (coke) in the centre housing;

- Physical damage to the turbo’s rotating parts and excessive bearing clearance (possibly caused by other failure modes);

- Excessive crank case pressure (blow-by from worn piston rings/bores);

- Fitting the incorrect turbocharger.

Preventing future oil leaks:

- Ensure air and oil drain systems are clear from blockages or restrictions;

- Check the exhaust system to make sure there are no leaks present;

- Ensure DPF (diesel particulate filter) and Catalytic converter is free of blockages.

Please note: Oil leaks can occur on VSR (high speed) balancing machines as the ambient pressures required to create the seal are not present as no housings are used. This can then force out oil from both the compressor end and turbine end giving the impression of a leak. This is unlikely to occur when the replacement turbo is fitted to the engine.

An oil leak can also occur when engines are running on idle. The pressure within the housings is lower, which in turn can lead to a vacuum being created, causing the oil to leak into the turbine housing. Once the engine starts to run at normal speeds the pressures will be restored and the leaks will stop. For further information on this or other topics, please contact Melett Technical Support – melett_sales@wabtec.com.